Smart Phone Interface Design for Accessing and Using MIT’s Recreation Facility during COVID19

Because of COVID19, most MIT facilities were closed during the first half of 2020. Starting from July 13th, 2020, MIT reopened a limited number of outdoor recreation facilities, including the Steinbrenner Stadium, Jack Barry field, and outdoor tennis courts. On September 8th, indoor recreation facilities, such as the Zesiger center (Z center), were reopened.

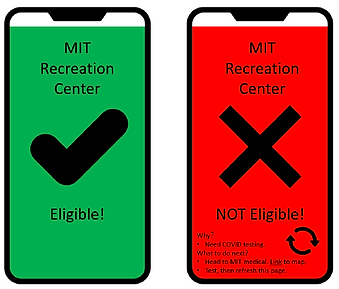

Accessing the MIT recreation system is not a straightforward process. One should first sign the liability waiver on DocuSign, a digital online service to securely sign documents. Then, one should visit one of the MIT COVID testing centers and pass the test. They will also need to submit daily COVID attestation on the MIT Atlas system. Then, the user will need to check the current opening hours, before navigating to the correct entrance. Lastly, for outdoor facilities, a recreation staff will check the eligibility of the user, before finally granting the user access to the facility.

The current process of gaining access to the MIT recreation facility is complex and cumbersome. Users could be easily confused by the fast-changing information and new entrance location of the facilities. Multiple scattered tasks also make it easy for users to miss a step, and as a result, fail to gain access. The system is also prone to time lag and users could waste valuable time waiting for the Atlas medical result to be transferred to the recreation system’s card readers. To gain final access to the facility, a lot of word exchange also happens between staff and users. The users heavily rely on staffs to inform them what the next steps are.

To tackle the problems described above, a centralized, timely, easy-to-use, and clear system should be developed to assist users to enter the MIT recreation system. In this report, I dig deep into the problem definitions, key stakeholders, and propose a system to address the issues.

Behavioral and Physiological Monitoring in Virtual Reality (VR)

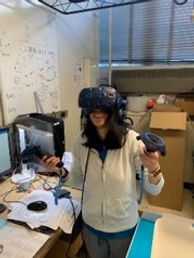

One of the most interesting fact about virtual reality (VR) is - what you see does not necessarily equal to what you feel. However, during hand eye coordination tasks, people tend to rely on both visual and proprioception feedbacks. I utilized the special ability of VR and designed an user study to investigate how the display of the user's body would affect the performance in VR pointing tasks.

For the VR scene, I created a target pointing system in Unity. The scene includes a target that randomly spawns in 18 designated locations in the 3D space. The pointing finger location is tracked by a Leap Motion Sensor attached to the front of the headset. I also designed and constructed a target system in the real world to provide haptics feedback. The system is actuated by 9 servo motors, and can bring the physical targets to their designated locations at a just-in-time basis.

This study is approved by MIT IRB. Subject recruitment, data collection, and data analysis were conducted in early 2021. Please find draft paper link here.

Developing a Room-Scale Haptic Feedback System for Virtual Reality (VR)

Within the past few decades, there has been a rapid development of virtual reality related technologies. The major development of such technologies was mainly focusing on visual and auditory sensorial channels, while the improvement of haptic feedback (sense of touch) has been lagged behind. The most commonly seen haptic interfaces, such as haptic gloves and Joycons, are only able to provide small-scale force/vibration feedback. Large and room scale haptic feedback is an area that is newly recognized and needs to be developed.

During the summer of 2019, I focused on developing room-scale haptic solutions for virtual reality experience. I first constructed the “Virtual Wall”, a scalable, moving mechanism that can generate direct contact response to the user. The mechanism mimics a solid wall, but different shapes can also be attached to the end effector. This work is published on the ASME digital collection website.

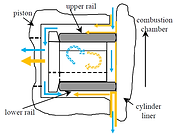

Modeling of Three-piece Oil Control Ring

Three-piece oil control ring (TPOCR) is one of the crucial components of the piston ring assembly. It is used to regulate the lubricant oil supply in most of the modern gasoline engines.

During my research in the Sloan Automotive Laboratory at MIT, I focused on building and improving the computational model of the TPOCR. The model allows the users to understand the dynamics and lubrication effect of the TPOCR.

The model is used to study the gas and lubricant oil flow around TPOCR

Three-piece oil control ring

Correlation of hydrodynamic pressure was developed by applying Reynolds equation to the ring profile

Surface roughness effect of the liner was considered in the correlation

Computational Fluid Dynamics Study on TPOCR groove

It was found from experiment that lubricant oil tends to be trapped between the two rails of the TPOCR. Therefore, I used CFD tool, ANSYS FLUENT, to study the flow pattern of the lubricant oil in the TPOCR groove. It was found that even blow-by happens in the groove, the incoming air does not create much flow in the pitches of the ring, which leads to one of the reasons that cause oil accumulation between the rails.

Studying the gas flow in the TPOCR groove with ANSYS FLUENT

Structural Study Using Mathematical Model & Finite Elements Analysis (FEA)

It was assumed by some that the side sealing effect of the TPOCR is caused by ring buckling. Therefore, I created mathematical model to study the buckling effect of the TPOCR. The bending and twisting stiffness of the TPOCR used in the model was calculated by FEA with SolidWorks Simulation. Mathematical model was also used to prove the correlation between the stiffness and the wire thickness of the TPOCR. Buckling of the TPOCR was also proved to be exist and is under further investigation by MAHLE.

FEA on bending and twisting stiffness of different components of TPOCR, the result is used for buckling calculation.

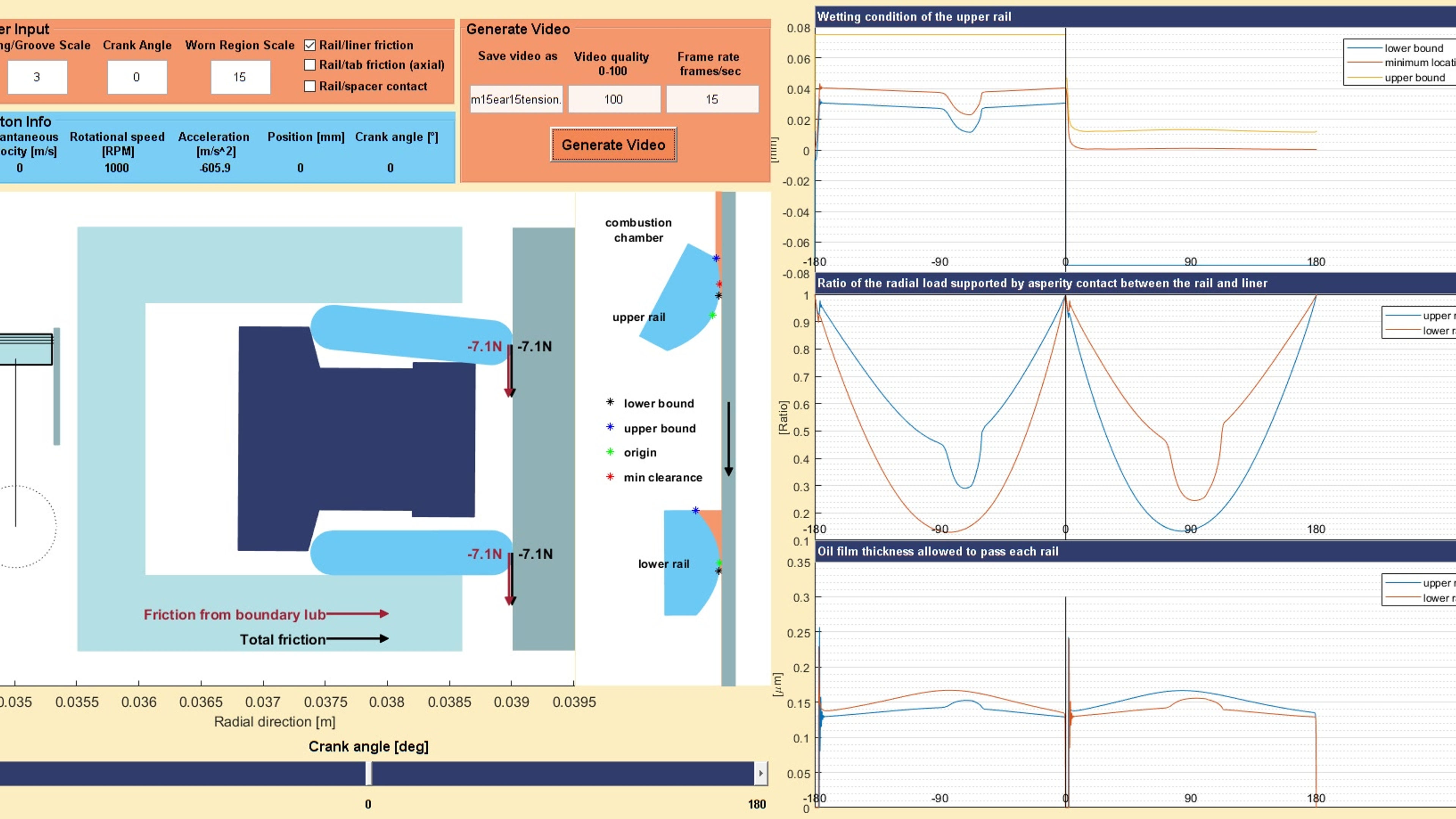

Designing User Interfaces to Visualize the Modeling Result of TPOCR and Ring Pack

My favorite part of working in Sloan Automotive Laboratory is designing user interfaces to visualize the modeling results. The idea of designing the visualization tools comes from taking Visual Computing I (4.521) with Professor Terry Knight in spring 2018. In the class, we learned how to use shape grammar to create rule-based design. For the final project of the class, I created the first prototype of the animation tool. The tool was capable to show the dynamic movement of the TPOCR. The animation was strongly praised by Professor Knight and Dr. Tian Tian. Later in early summer of 2018, I gained approval from Dr. Tian to design user interfaces to create animations. Designing the user interfaces not only helps the users of the model to better understand the data, but also allows me to develop my artistic skills.

Currently there are two visualization tools available: one for TPOCR and the other for the ring pack.Both tools allow users to magnify certain geometry to show the detail of the design. The tools display modeling result chosen by the user, and can save the animation as a video.